PeterH

-

Posts

1,496 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Posts posted by PeterH

-

-

And I understand that slow-cooling can add to the available effects from some glazes in electric kilns, by giving them more time to develop crystals.

Super Cool! Slow Cooling in an Electric Kiln

https://ceramicartsnetwork.org/daily/article/Super-Cool-Slow-Cooling-in-an-Electric-Kiln

From https://digitalfire.com/picture/bestenazoh

Firing for Atmospheric-like Effects in an Electric Kiln https://tinyurl.com/cf7ef94y

Fuel-burning kilns tend to be much larger than electric kilns. Because of their size, they usually have a slower heat rise, a soak at the top temperature, and slower cooling cycles. If you want similar results from an electric kiln, especially when firing to cone 6, one of the most important things you can do is emulate the heating and the cooling cycles of larger kilns. This means slowing the temperature gain to about 100°F (38°F) an hour during the last several hours of the firing, soaking the kiln at the top temperature, and then down-firing to slow the cooling cycle.

Electric kilns are built with thinner insulation and legs (to allow for air circulation), and they cool very quickly, especially at higher temperatures. If you are seeking buttery, matte surfaces but have trouble achieving them in the electric kiln, it is most likely due to fast cooling. Matte surfaces are usually caused by microcrystal growth during cooling, and, if the cooling cycle is too steep, there isn’t enough time for crystals to develop. In extreme cases, I’ve even seen matte glazes go glossy and transparent.

... note that the 100F(38C) above is "finger trouble", see

What is the difference between fahrenheit degrees and degrees fahrenheit? https://digitalfire.com/picture/2704- Jeff Longtin, Babs, Hulk and 1 other

-

4

4

-

8 hours ago, ThruTraffic said:

I found one YouTube video in english that was created by a researcher in Europe. I 'think' I understood he was able to recreate the Roman/Greek level of gloss without a deflocculant but at great effort by manually adding clay to water (hours of doing it slowly with his fingers). His fired results certainly did look as glossy as ancient terra sig pottery.

Can you give a reference? It would be interesting to know why he chose to mix by hand rather than mechanically, sounds a bit hair-shirt to me.

You may find parts of this video of interest, especially from about 24m to 31m. It describes the gradual realisation of the nature of the slip used in antiquity for things like Greek red-and-black and "Roman" Samian ware.

Terra Sigillata: Lost & Found by Peter Pinnell & Rhonda Willers

Long before glazes appeared, clay finishes were widely used. Potters around the Mediterranean developed surfaces employing the unique properties of clay. Once lost, Terra Sigillata was found after 1500 years. This co-lecture provides a history of this surface with an overview of today’s practices.... of course this doesn't say how it was made. I suspect this is lost in history. I doubt deflocculation would leave identifiable traces, and it the process may well have been a trade/craft secret.

Use of deflocculants such as soda/pearl ash would have been possible. I've even seen a suggestion that a good way to find a natural source is to wait a decade or so for a major drought and then explore the dried-up beds in the local lakes. Some of them will consist of ultra-fine particles (sort of a super ball-clay*). Personally I've wondered if waste-water from the production of clay for the bodies could have been a starting point, as it would probably have contained colloidal particles.

* Supposedly the change of pH when river water enters a lake favours the precipitation of colloidal particles, potentially leading to a very fine silt.

PS The video quotes the historic use of the term "magnetic" - obviously we would now say "electrostatic".

-

3 hours ago, StephSlone said:

Any thoughts out there?

I think this is the right manual

Duncan Energy-Saver ES & EA Instruction Manual LX851

https://eadn-wc04-7751283.nxedge.io/wp-content/uploads/LX851_Duncan_Energy_Saver_Owner_Manual.pdfOn p13 it says

What is the relationship between your "clock-face" numbers and any labels on the on the kiln, such as

... and why doesn't this picture show anything that obviously corresponds to the "low" marking mentioned in the manual?

Unless "off" in the picture is the equivalent of "low" in the manual? Which makes some operational sense (as you report that it does heat up the kiln) but no linguistic sense.

-

22 hours ago, neilestrick said:

What model is the controller on the kiln? Kiln companies don't typically make their own, so you may be able to find a manual for it that shows a setting for thermocouple type.

Still a very good question.

-

1 hour ago, l.mourad6663 said:

Hy my friends my question

Is a certain concentration of sodium silicate solution required in the casting process?

First a brief statement of the pros and cons from

Understanding the Deflocculation Process in Slip Casting

https://tinyurl.com/2p96x33r

BTW https://digitalfire.com/ is a great site for background reading

So, it's a bit more complicated than simply adding x% of a deflocculant. For a given clay/water mix you are basically trying to add defloculant to achieve a low viscosity, while keeping safely away from the over-deflocculation ... and hoping that the result doesn't gel unacceptably.

A comprehensive process to do this from scratch is given in:

Determining Dispersant Additions for Casting Slips

https://tinyurl.com/34khjunrEven if you don't do things this way it gives a clearer picture of what you are trying to achieve.

PS I understand that the modern polymer deflocculants (eg Darvan) give superior results, are easier/more-foolproof to use, and damage the moulds less. While many sodium silicate based slips also benefit from the addition of soda-ash/sodium-carbonate. [Warning: Darvan should be store above 10°C.]

-

Any relevance, or are there too many non-standard cables about?

Thermocouple Cable Colour Chart

https://www.pyrosales.com.au/blog/thermocouple-information/thermocouple-cable-colour-chart/...and

https://www.hgsind.com/videos/how-identify-thermocouple-wire-color

In this video we’ll be focusing on the ANSI wire color coding used by the United States and Canada. -

-

Googled across this image transfer technique. It uses a laser-printed image to produce a one-time transfer "plate" needing to be inked up.

How to Create an Underglaze Transfer using a Photocopy , Our Halloween Project

https://www.baileypottery.com/blog/post/print-out-photocopy-transfer-in-halloween-style.htmlPS Sorry @oldlady's image transfer pics are gone. Some tiny snippets of Kim Kirchman’s work

30 second video of her painting an image https://www.youtube.com/watch?v=NVNuEJU5uQ8A still of a different image being pulled, looking pretty crisp https://www.instagram.com/p/CRMUaH2DBQ8/

Low resolution video of an image transfer at 7:38ish in https://youtu.be/-txcJjLjQZ0?t=421

-

Can you post a close up of the plate?

-

1 hour ago, cafedunier said:

but how on earth do I determine what cone it matures at?

This is a very informative site:

Maturity https://digitalfire.com/glossary/maturity- Hulk and Kelly in AK

-

2

2

-

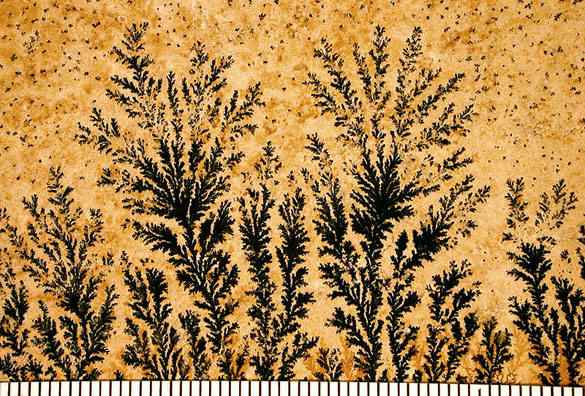

BTW I quite like this colour combination, and the visual interaction with slightly blotchy background.

... its a manganese dendrite, typically formed by manganese rich water seeping into a crack in a limestone bed.- Ben xyz, Pir, Callie Beller Diesel and 1 other

-

4

4

-

A low-tech way of achieving a deflocculated slip is find a bed of clay which deflocculates well when alkalies -- such as soda ash or wood ash -- are added. When this happens it can be because the clay contains tannins or lignite/lignates.

Taking a more chemically informed and proactive route both tannins and alkali can be added directly, as in:

Mechanisms for efficient clay dispersing effect with tannins and sodium hydroxide

https://tinyurl.com/m5w2cyz8Tannins appear to be fairly easily extracted from natural sources, and historically may already have been in use in the tanning industry.

How to Extract Oak Tannins https://www.ehow.com/how_12001502_extract-oak-tannins.htmlA paper recommending the use of tannins for deflocculating drilling mud:

Evaluation of a Naturally-derived Deflocculant (Terminalia Chebula) in Bentonite Dispersions

https://tinyurl.com/5n6crm5rPS Also found this reference, but have not managed to access the text. The book is available for ~£35

... I expect this relates to current practice, and is not inconsistent with the use of something more like water-slip than deflocculated slip. -

Just maybe relevant:

Slipcasting https://npceramics.wordpress.com/2017/09/06/slipcasting/

Historically, there’s seems to be some debate as to when slipcasting was actually ‘invented’. It is fairly widely documented as being a process that became established as a viable manufacturing method around 1745. This is when both deflocculated slips and plaster of Paris moulds were readily available. Prior to this ‘water slip’ had been used for casting, but it had a variety of disadvantages; the main on being the saturation of the moulds. This not only drastically shortened their working life, but it also took ages for the plaster to dry out between each casting. And any casts that were then successfully removed were prone to high rates of shrinkage and distortion, due to their high water content. Overall, this meant the failure rate from start to finish was uneconomically high.

... it then goes on to mention Peruvian panpipesMy understanding is that the Dawson's paper you referenced is suggesting that the pipes were cast individually* and then joined by adding additional clay by hand. This sounds like a relatively undemanding requirement, so perhaps a relatively low-tech casting technology would be adequate.

* Although the set of pipe moulds for a complete panpipe were held in a common structure.Chinese slipcasting is probably a different story, but so far I've only found statements that is was done and not found any description of the pots produced (let alone the process).

-

On 10/15/2022 at 2:19 PM, Pir said:

I used two acid "inks"--manganese (which turned brown, sadly--has anyone used black stain?) and red iron oxide.

Robin Hopper confirms that the use of stains is OK in

Mocha Diffusion

https://ceramicartsnetwork.org/pottery-making-illustrated/pottery-making-illustrated-article/Mocha-Diffusion#A comparison of different "pigments" "acids" is given in

An Exploration of the Variables Involved inCreating Mocha Diffusions

https://francesgwilliamceramics.files.wordpress.com/2019/06/an-exploration-of-the-variables-involved-in-creating-mocha-diffusions-frances-gwilliam-st20086157.pdf

... on p21 it states that

At stoneware temperature there is colour loss in the tendrils. The main body has the same

metallic brown as it has at the unglazed earthenware stage, but is slightly shinier. When glazed

the colour is almost completely absorbed. Even on the main body the colour vibrancy

decreases significantly. The tendrils become very faint lines.

Manganese Oxide works well initially as colourant for mocha diffusion, but I wouldn’t suggest

using it above earthenware temperature with glaze. The colour stays mostly consistent

through firing temperatures but is absorbed too much by the glaze at higher temperatures.PS Stumbled across these, which might be of interest

A rather "different" style of feathering

See https://www.youtube.com/watch?v=cSrWRWILaZoThought provoking eye-candy

Satisfying Mocha Diffusion Compilation

https://www.youtube.com/watch?v=WjocYCaPsUMAnd a classroom science paper in Japanese (Google translate doesn't seem to work).

Fractal growth method applicable in class: Fractal dimension and growth characteristics of Mocha diffusion patterns with surfactant

https://tinyurl.com/mr3hfj6v

The pattern when the dye solution containing polysorbate80, a surfactant, was dropped on a 1: 1 mass ratio of kaolin and water was analyzed.so it's definitely not a pottery experiment, but it does raise some interesting questions

- would surfactants work instead of the usual "acids" (e.g. washing up liquid or dishwasher rinse aid)

- as altering the concentration of the surfactant influences the "openness" of the pattern, would watering-down the concentration of the acid have a similar effect? Maybe 50:50?

-

2 hours ago, kswan said:

Is there a way to find out water's hydrophobic reaction to clay/glaze materials, or is that something to just test out on my own? I seem to recall something about this in the back of my brain somewhere, that you can check this on fired glazes by putting a drop of water on it and seeing how much it spreads out or forms a ball.

Are you thinking about measuring the contact angle? My knowledge of the subject ends with its name, but here are a couple of google hits:

Contact Angle: A Guide to Theory and Measurement

https://www.ossila.com/pages/contact-angle-theory-measurement

... which a least has some helpful picturesSimple Contact Angle Measurement using a Smartphone (Easy Guide)

https://www.youtube.com/watch?v=s3DrTJk3CFA

... which tries to offer a half-way house between judging things by eye and the use of specialised equipment -

Two trivial points.

They sell water-repellent treatments for windscreens. I don't expect they are food safe, but they might give you an idea how useful a really water repellent surface would be on an experimental spout.

Not too certain about this, but epoxy may have a lowish surface tension. IIRC people have mentioned food-safe epoxy in other postings.

Typical values of surface energy for materials and adhesives

https://www.twi-global.com/technical-knowledge/faqs/faq-what-are-the-typical-values-of-surface-energy-for-materials-and-adhesivesMay be true

Food Safe Epoxy – Helpful Guide about Food Grade Epoxy

https://resin-expert.com/en/guide/food-safe-epoxyPS I expect that the matt surfaces of super-hydrophobic substances would get clogged over time (BTW I live in a very hard-water area).

How to Prevent Teapots from Dripping

https://news.softpedia.com/news/How-to-Prevent-Teapots-from-Dripping-125869.shtml

-

1 hour ago, Pir said:

and I suppose finding the volume of the dry materials wouldn't be helpful, as dry glaze powders aren't measured by volume (at least not by me).

Don't go there, these formula use the "particle density" rather than the "bulk density".

See wiki for the full story:

https://en.wikipedia.org/wiki/Bulk_density

https://en.wikipedia.org/wiki/Particle_density_(packed_density)But imagine a quantity of sand. It's weight is easy, but what is it's volume? You can measure it in a measuring cylinder, getting a value for sand plus inter-grain air. Or you can pour it into a measuring cylinder already containing some water, and see how much the volume increases (avoiding measuring any trapped air).

-

26 minutes ago, Tina01 said:

Now unfortunately I can't do it with such a precision, (in 0.1 of grams). But for sure I will keep trying

What is (probably) important is that you add the bentonite in very small quantities, preferably sprinkled over a significant area. Then allow a little time before agitation, as you really want the bentonite to drop through the surface into the water of its own accord.

IIRC the way it would be done in a lab is to place all the bentonite in a thin line on a glazed tile. Then cut small lengths off the line as required with a sharp edge (traditionally a razor blade).

-

20 hours ago, Pir said:

Brongniart’s formula, as it's written, with the -1 and the 1-1 etc., still doesn't compute for me

I assume you mean

Can you elaboration on your problems? After an initial abortive attempt, I re-read it's documentation* and then it seemed to work fine for me.

Mwet = your weight of glaze in bucket = 2640

Swet = your measured specific gravity = 1.42

Sdry = Brongniart’s recommended value = 2.6giving Mdry = weight of glaze powder in the bucket = 2640*(1-1/1.42)/(1-1/2.6)

Plugging this into google gives 1268.9 again

* As they say in software engineering, if all else fails RTFM (read the f-ing manual). A tribute to the the fact that much of the available documentation is often inappropriate or of poor quality.

-

And if all else fails there are "equation solvers" about which can perform some of the legwork, such as:

Equation Solver https://www.dcode.fr/equation-solver

Input

60*1000/1.7 = 4/3*pi*(50/2)^2*55 - 4/3*pi*(50/2-t)^2*(55-t)

v = 4/3*pi*(50/2)^2*55

c = 4/3*pi*(50/2-t)^2*(55-t)... and ask it to solve for t gives you

Only time I've had to use it so far was calculating the likely wall thickness of a Qvevra!

... and how sweet it still remembers the calculation for me.

-

3 hours ago, Tina01 said:

p.s. As many times mentioned in this thread that bento can absorb water 15x its weight, 5g could absorb 75g, or 75ml water. However what I see is more than 50ml is still free water.

I really hope it isn't necessary to try it, but I found this test method

TECHNICAL NOTE -BENTONITE SWELL INDEX

https://globalsynthetics.com.au/wp-content/uploads/2016/05/TECHNICAL-NOTE-SWELL-INDEX.pdf

ASTM- D5890 is used to determine the swell index. A 2g sample of dried and finely ground bentonite clay is dispersed into a 100 ml graduated cylinder in 0.1g increments. A minimum of 10 minutes must pass between additions to allow for full hydration and settlement of the clay to the bottom of the cylinder.

These steps are followed until the entire 2g sample has been added to the cylinder. The sample is then covered and protected from disturbances for a period of 16 - 24 hours, at which time the level of the settled and swollen clay is recorded to the nearest 0.5 ml.

...

While the sodium bentonite clay utilized in Bentofix® GCLs typically meets a Swell Index in the range of 24 ml – 36 ml, the targeted minimum value is 24 ml /2 g. This minimum value will generally ensure the specified performance of a GCL product is achieved.Obviously 24-36 ml/2g = 60-90 ml/5g, and note (presumably active) dispersion of 0.1g increments.

PS Should you try this -- and it gives an acceptable result -- maybe your bentonite is just extra difficult to wet. In which case using pre-slaked bentonite could be

importanthelpful when making additions to your clay. -

No I haven't used the calculator "in anger".

11 hours ago, Pir said:As I said, I'm not mathematically inclined, so this reverse engineering might be terribly obvious,

It's not you maths, it's your modelling/physics that's leading you astray.

IMHO it's a tricky and superficially misleading problem. After all a glaze is a "liquid" containing heavier-than water particles that aren't setting out (or at least only doing so slowly) and you don't meet too many of them.

I've got a (very old) degree in maths & physics and still cannot just "see" what the formula should be, I have to go back to basics and start with:

SG-of-glaze = weight-of-glaze/volume-of-glaze

weight-of-glaze = weight-of-water + weight-of-glaze-powdervolume-of-glaze = weight-of-water/SG-of water + weight-of-glaze-powder/SG-of-glaze-powder

Once you can agree with that, the rest is just arithmetic.

... Or find a calculator to do it for you. Thank @Minfor the reference.PS Google makes quite a good calculator: enter 1371.1/1.0 + 1268.9/2.6 and you get

... I expect other browser do the same. -

780

6 hours ago, Pir said:I guess I'll see how the test tiles turn out!

That's what the calculator gives me as well.

SG of glaze 1.42, Weight of glaze in the bucket.

Calculator gives weight of dry ingredients 1268.9g

5% of 1268.9 = 1268.9*5/100 = 63.444g stain

-----------

So what's going on?First Brongniart's calculator gives results consistent with its model (glaze-powder is insoluble and has a typical SG of 2.6).

Your figures are weight-of-glaze-powder= 1268.9, so weight of water = 2640 - 1268.9 = 1371.1 and SG = 1.42Now volume-of-glaze = weight-of-water/SG-of water + weight-of-glaze-powder/SG-of-glaze-powder

= 1371.1/1.0 + 1268.9/2.6 = 1859.1

So SG-of-glaze = weight/volume = 2640/1859.1 = 1.42-----

Now you calculations gave weight-of-water = 1859, and weight-of-glaze-powder = 780

If this were true then ...

volume-of-glaze = weight-of-water/SG-of water + weight-of-glaze-powder/SG-of-glaze-powder

= 1859/1.0 + 780/SG-of-glaze-powder

= 1859 + 780/SG-of-glaze-powder

and SG-of-glaze = weight/volume = 2640/(1859 + 780/SG-of-glaze-powder)

substituting SG-of-glaze-powder = infinity gives SG-of-glaze = 1.42 (the measured value)

So the calculations you are performing assume that the insoluble glaze powder has an infinite SG (ie zero volume). Which obviously isn't true.--------------------

Double checking, if you apply the calculator with a stupidly high SG for for the dry ingredients it approaches you estimate for the dry weight.

-

terminological confusion?

6 minutes ago, Steve Hoffman said:On a past project, an experienced ceramist had mixed up some brown stain that worked well for that piece and I thought it might be a good base for this one. She advised that I only had to mix with water.

I think there is some terminological confusion here.

When potters talk about stains they usually mean things like mason stains, which can be described as:

Stains are dry powders made by firing selected oxides proportioned to produce stable crystals of consistent colour resistant to high temperatures and glaze attack. Ceramic stains are used to create coloured glazes, underglazes, and clays & slips.https://psh.ca/pages/mason-crysanthos-ceramic-glaze-stains

(IMHO pigment would have been a much better choice of term, and seems to be what's used when describing paints or inks.)

What you are referring to as a stain sounds more like an underglaze in potter-speak (or possibly a slip or an engobe).

Underglazes are used in pottery to create designs and patterns that come up through the glaze covering them. This can give the surface more visual depth and character. Although they are often used under clear glazes, they can also be used under other, generally light-colored, transparent glazes. https://www.thesprucecrafts.com/what-are-underglazes-2746191I'm definitely not saying your terminology is "wrong" in any sense. Just when talking about anything it minimizes confuse if we all use the same terminology.

BTW I've used fairly random definitions plucked from the net, just to give an idea of their usage.

@Min's suggestion that you post a picture of something close to what you are aiming for is a very good one, and the responses to it will help establish the the right pottery terminology (and products to use).

PS A random selection of pictures of the craw glazes she mentioned at https://tinyurl.com/2865ec3z

Ditto for reticulated glazes at https://tinyurl.com/yck9hmue

... but be warned some of them are difficult/antisocial to use/control (I remember one was described as "spits like an an orangutan in the kiln")

Dipping vs Brushing

in Clay and Glaze Chemistry

Posted · Edited by PeterH

Lots of pix at https://tinyurl.com/2rkyb27z ... two particularly lo-tech ones are

It would be interesting to know if "fingerdips" work

Use a car dent puller to dip your pots in glaze! https://tinyurl.com/2p9y6bn3\\\\\\\\\\

Apparently suckers can be useful in some circumstances